Unraveling the Intricacies of Laser Engraving Machines: A Comprehensive Guide

Understanding the Basics of Laser Engraving

Laser engraving is a fascinating process that uses laser technology to etch designs onto various materials. This method is known for its precision and ability to create intricate patterns that would be challenging to achieve manually. The laser engraving process involves directing a concentrated beam of light onto a surface, which removes material and creates a permanent mark. The technology is widely used for personal projects, industrial applications, and even artistic endeavors. Understanding the basics of laser engraving is crucial for potential buyers as it sets the foundation for selecting the right machine.

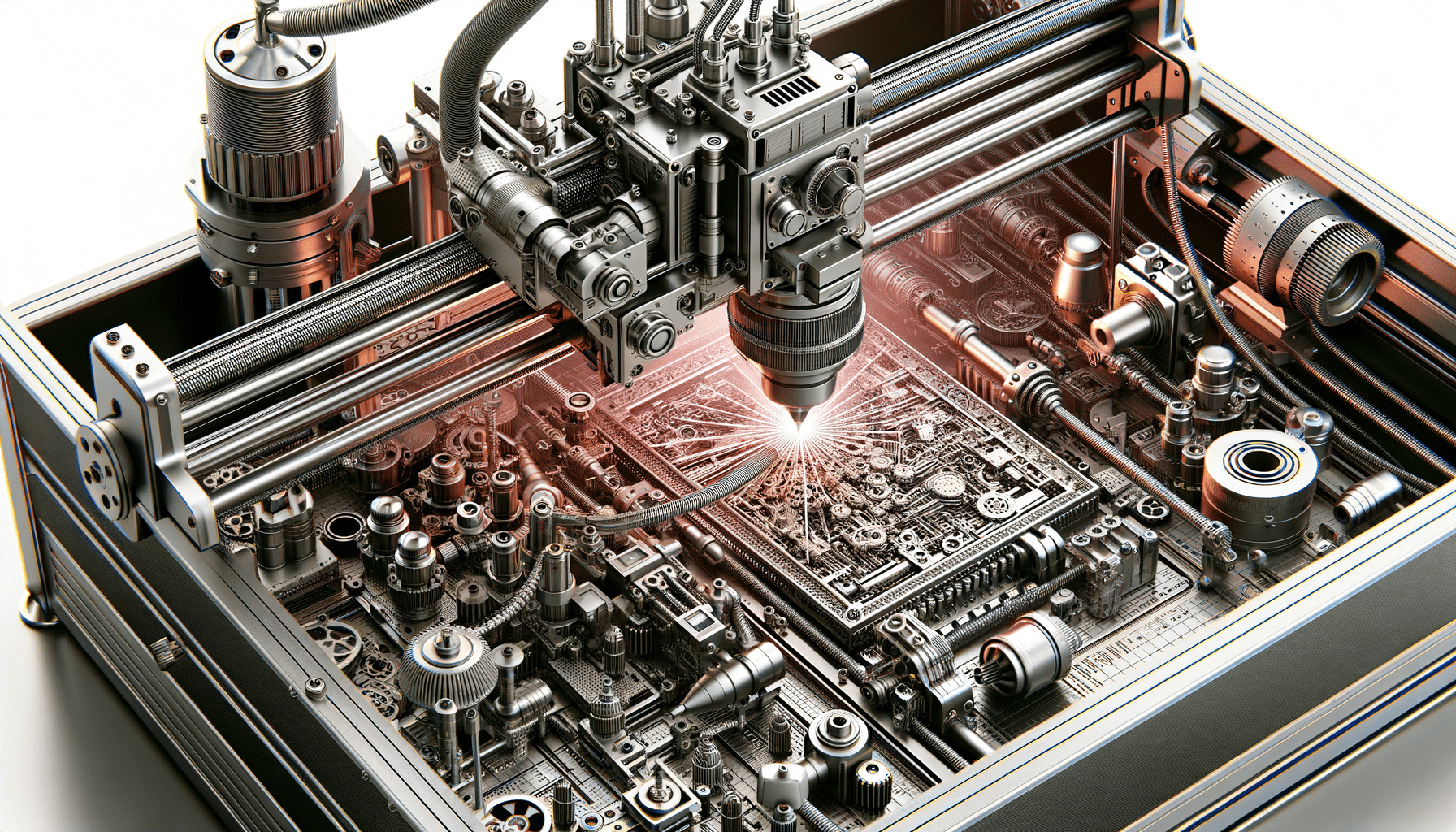

There are several key components in a laser engraver, including the laser source, the controller, and the work surface. The laser source generates the beam, the controller manages the movement and intensity of the beam, and the work surface supports the material being engraved. Different types of lasers, such as CO2, fiber, and diode lasers, offer varying capabilities, making it essential to choose one that aligns with your needs.

Laser engraving can be applied to a multitude of materials, including wood, metal, glass, and plastic. Each material reacts differently to the laser, impacting the depth and quality of the engraving. For instance, wood is relatively easy to engrave and produces a nice contrast, while metal requires more power and precision. This versatility makes laser engravers a popular choice for hobbyists, artisans, and businesses alike.

Key Considerations for Choosing a Laser Engraver

Selecting the right laser engraver involves evaluating several factors to ensure it meets your specific needs. One of the primary considerations is the type of projects you plan to undertake. If you are primarily working with non-metal materials such as wood or acrylic, a CO2 laser engraver might be the most suitable choice. However, if you intend to engrave metals, a fiber laser engraver would be more appropriate due to its ability to handle tougher materials.

Another critical factor is the size of the work area. Laser engravers come in various sizes, and the work area determines the maximum size of the material you can engrave. For larger projects, a machine with a more extensive work area is necessary, while smaller, more compact machines are sufficient for minor projects or limited workspace.

Budget is also an essential consideration. Laser engravers range from affordable models for beginners to more expensive, industrial-grade machines. It’s crucial to balance cost with the features you need to avoid overspending on unnecessary capabilities. Additionally, consider the machine’s software compatibility, as user-friendly software can significantly enhance your engraving experience.

Exploring the Features and Capabilities of Laser Engravers

Modern laser engravers boast a variety of features that enhance their functionality and user experience. One notable feature is the ability to adjust the laser’s power and speed settings, allowing users to customize the engraving process based on the material and desired outcome. This flexibility is particularly beneficial for those working with diverse materials, as it enables precise control over the engraving depth and detail.

Some laser engravers include advanced features such as autofocus, which automatically adjusts the laser’s focus based on the material’s thickness, ensuring optimal engraving quality. Additionally, many machines offer connectivity options, including USB, Wi-Fi, and Bluetooth, allowing users to easily transfer designs from their computer or mobile device.

Engravers also vary in terms of their cooling systems, which are vital for maintaining optimal performance and preventing overheating. Air-cooled systems are common in smaller, less powerful machines, while water-cooled systems are often used in more robust models to handle higher power outputs. Understanding these features can help potential buyers choose a machine that aligns with their technical requirements and operational preferences.

Applications and Benefits of Laser Engraving

Laser engraving offers numerous applications across various industries, making it a versatile tool for both personal and professional use. In the manufacturing sector, laser engraving is used to mark parts and components with serial numbers, barcodes, and other identification marks. This process ensures traceability and compliance with industry standards.

In the world of arts and crafts, laser engraving enables artists to create detailed designs on a range of materials, from wood to glass. This capability allows for the production of personalized gifts, custom jewelry, and unique decorative items, enhancing the creative possibilities for artisans and hobbyists.

The benefits of laser engraving are manifold. It provides a high level of precision and consistency, ensuring that each engraving is identical, which is particularly important for large-scale production. The non-contact nature of laser engraving also reduces the risk of damaging the material, making it suitable for delicate or fragile items. Additionally, the process is relatively fast and efficient, allowing for quick turnaround times and increased productivity.

Maintenance and Safety Tips for Laser Engravers

Proper maintenance and safety practices are essential to ensure the longevity and safe operation of laser engravers. Regular cleaning of the machine’s components, such as the lens and mirrors, is crucial to maintain optimal performance and prevent damage. Dust and debris can accumulate over time, affecting the quality of the engravings and potentially causing malfunctions.

Safety is paramount when operating laser engravers. Users should always wear appropriate protective eyewear to shield their eyes from the laser beam, which can cause serious injury. It’s also important to ensure the work area is well-ventilated, as some materials can produce hazardous fumes when engraved. Many machines come equipped with exhaust systems to help mitigate this risk.

Routine inspections and maintenance checks are recommended to identify and address any potential issues before they escalate. This proactive approach helps prevent costly repairs and downtime, ensuring the machine operates smoothly and efficiently. By adhering to these maintenance and safety guidelines, users can enjoy the benefits of their laser engraver for years to come.