Fascinating Insights into the World of Welding

The Art and Science of Welding

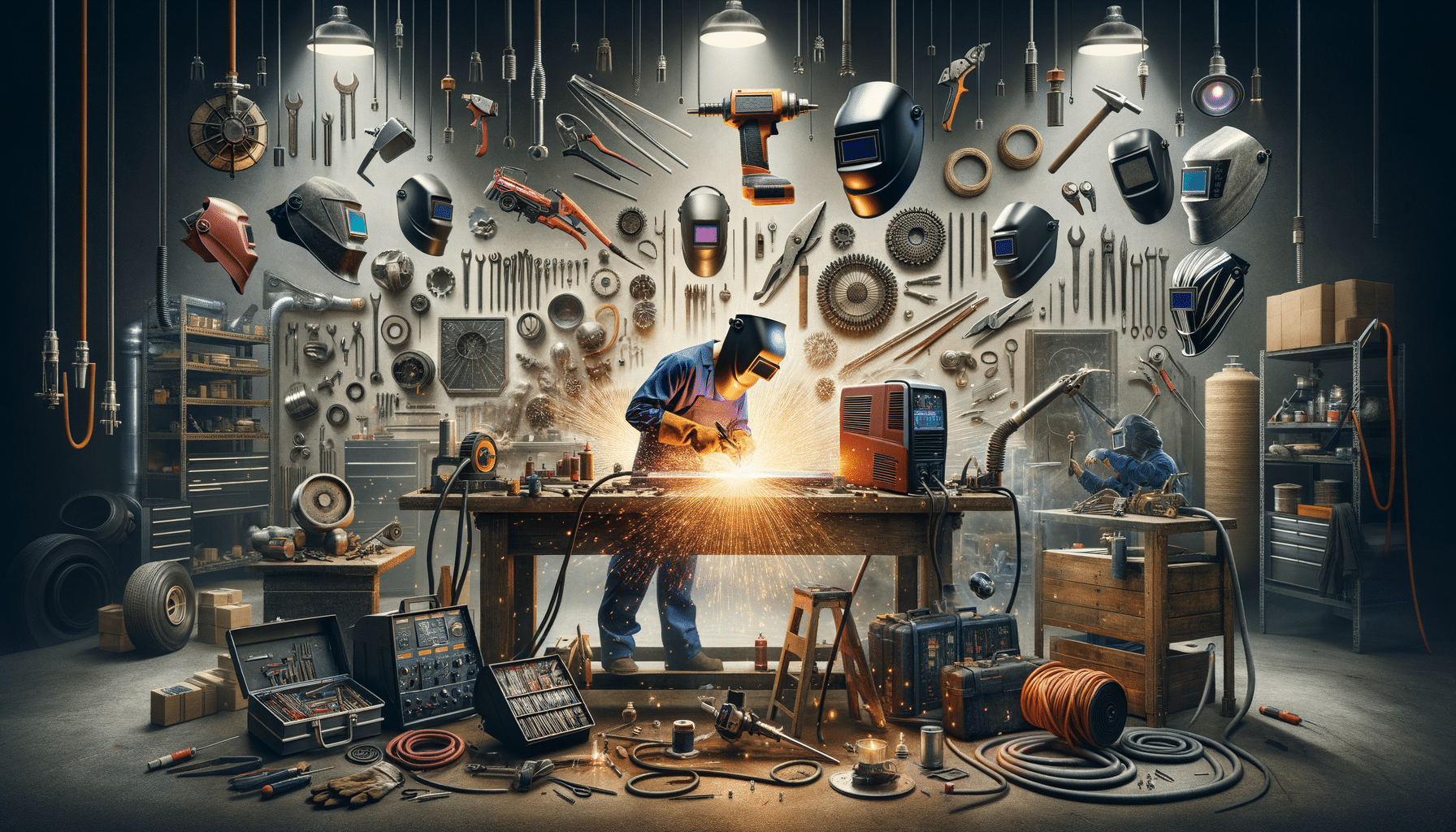

Welding is a unique blend of art and science, requiring both technical skill and creative insight. At its core, welding involves joining materials, typically metals, by melting the parts together and allowing them to cool, forming a strong bond. This process is not just about brute force and heat; it requires precision and an understanding of materials’ properties. The science lies in understanding how different metals react under heat and pressure, while the art is in the welder’s ability to manipulate these elements to create a seamless joint. The welder’s expertise is crucial in ensuring that the bond is not only strong but also aesthetically pleasing, especially in industries where the appearance of the weld is as important as its strength.

Diverse Applications Across Industries

Welding is a critical process across a multitude of industries, each with its unique requirements and challenges. In the automotive industry, welding is used to assemble vehicles, ensuring that they are both safe and durable. In construction, welders are responsible for creating the frameworks of buildings, bridges, and other infrastructures. The aerospace industry relies on welding to create lightweight yet strong structures for aircraft. Each application requires specialized techniques and equipment, highlighting the versatility and importance of welding in modern manufacturing and construction.

Technological Advancements in Welding

The welding industry has seen significant technological advancements over the years, enhancing both efficiency and safety. Automation and robotics have become increasingly prevalent, allowing for more precise and consistent welds. These technologies reduce the risk of human error and improve productivity. Additionally, advancements in welding materials and techniques, such as laser and electron beam welding, have expanded the possibilities of what can be achieved. These high-tech methods allow for welding in environments and conditions that were previously challenging or impossible.

Welding Safety and Training

Safety is a paramount concern in the welding profession due to the inherent risks involved. Welders must be trained to handle equipment safely and to recognize potential hazards. Protective gear, such as helmets, gloves, and aprons, are essential to protect against burns, sparks, and harmful fumes. Comprehensive training programs are crucial, providing welders with the knowledge and skills needed to perform their tasks safely and effectively. Continuous education is also important, as it keeps welders updated on the latest safety protocols and technological advancements.

The Future of Welding: Sustainability and Innovation

As industries move towards more sustainable practices, welding is also adapting. The development of eco-friendly materials and techniques is becoming a focus, reducing the environmental impact of welding processes. Innovations such as friction stir welding and hybrid welding methods are being explored for their efficiency and reduced energy consumption. The future of welding looks promising, with a continued emphasis on sustainability and innovation driving the industry forward.