Mastering Precision: Your Comprehensive Guide to Understanding Laser Engraving Machines

Embrace the realm of laser engraving machines and tap into your creativity.

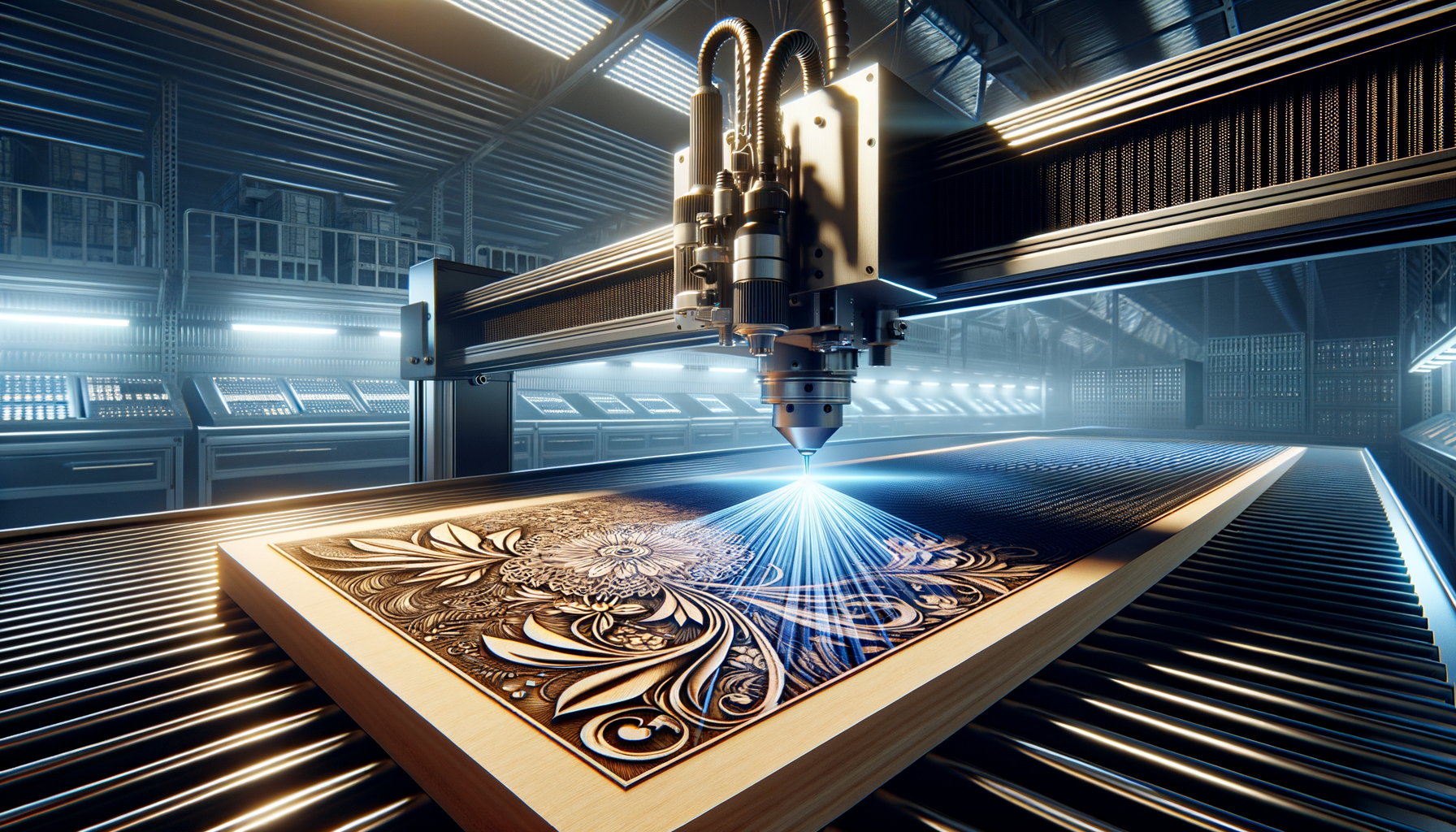

Understanding the Basics of Laser Engraving Machines

Laser engraving machines have revolutionized the way we approach precision art and manufacturing. These machines use laser beams to engrave or mark surfaces with exceptional accuracy, offering a level of detail that is difficult to achieve with traditional methods. The versatility of laser engraving machines allows them to be used on a variety of materials, including wood, metal, glass, and plastic. This adaptability makes them invaluable tools in industries ranging from jewelry design to industrial manufacturing.

At the heart of a laser engraving machine is the laser itself, which can vary in type and power. The most common types include CO2 lasers, fiber lasers, and diode lasers, each suited to different materials and applications. CO2 lasers are particularly effective for non-metal materials, while fiber lasers excel in metal engraving. Understanding these differences is crucial for selecting the right machine for your needs.

Laser engraving offers several advantages over traditional engraving methods. It provides a contactless process, reducing wear and tear on tools and materials. This not only prolongs the lifespan of the equipment but also ensures cleaner, more precise results. Additionally, laser engraving is highly efficient, capable of producing intricate designs at a rapid pace, which is ideal for both small-scale artisans and large production facilities.

Applications and Industries Benefiting from Laser Engraving

The applications of laser engraving machines are as diverse as the industries they serve. In the world of arts and crafts, these machines enable artists to create detailed designs on a wide range of surfaces, from personalized gifts to intricate sculptures. The ability to quickly switch between different materials and designs makes laser engraving a favorite among creative professionals.

In the industrial sector, laser engraving is used for marking parts with identifiers such as serial numbers and barcodes. This is essential for inventory management and quality control, ensuring that components can be easily tracked and verified throughout the production process. The automotive and aerospace industries, in particular, rely on laser engraving for its precision and durability, which are critical in maintaining safety and compliance standards.

Moreover, the medical field benefits from laser engraving for the labeling of medical devices and instruments. The precision of laser engraving ensures that markings are legible and long-lasting, which is vital for maintaining the integrity and safety of medical equipment.

Technical Aspects and Innovations in Laser Engraving

Laser engraving technology is constantly evolving, with innovations aimed at enhancing precision, speed, and versatility. Recent advancements include the development of multi-axis systems that allow for engraving on complex surfaces, expanding the possibilities of design and application. These systems use sophisticated software to control the movement of the laser, ensuring that even the most intricate patterns can be accurately reproduced.

Another significant innovation is the integration of artificial intelligence in laser engraving machines. AI algorithms can optimize engraving paths, reducing the time and energy required for each project. This not only improves efficiency but also minimizes the environmental impact of the engraving process.

Furthermore, modern laser engraving machines often come with user-friendly interfaces and connectivity options, allowing operators to easily upload designs and monitor progress. Wireless connectivity and cloud-based design libraries are becoming standard features, making it easier than ever for users to access and share creative resources.

Choosing the Right Laser Engraving Machine for Your Needs

Selecting the appropriate laser engraving machine depends on several factors, including the materials you plan to work with, the complexity of your designs, and your budget. For hobbyists and small businesses, entry-level machines offer a cost-effective way to explore the potential of laser engraving without a significant investment. These machines typically have lower power outputs and smaller work areas but provide sufficient capabilities for basic projects.

For professional and industrial applications, more advanced machines with higher power and larger workspaces are recommended. These machines can handle a wider range of materials and are equipped with features that support high-volume production. It’s also important to consider the software compatibility and ease of use, as this can greatly affect the efficiency of your workflow.

When evaluating different models, consider the following:

- Material compatibility: Ensure the machine can engrave the materials you intend to use.

- Power and speed: Higher power and speed can increase productivity but may come at a higher cost.

- Software and connectivity: Look for machines with intuitive software and flexible connectivity options.

- Support and warranty: Reliable customer support and a comprehensive warranty can provide peace of mind.

The Future of Laser Engraving Technology

The future of laser engraving technology promises even greater advancements, with potential developments in areas such as 3D laser engraving and increased automation. These innovations could open up new possibilities for customization and precision, allowing for more complex and intricate designs.

As the technology becomes more accessible, we can expect to see a broader adoption across various industries, from fashion to architecture. The ability to quickly and accurately engrave materials could revolutionize the way products are designed and manufactured, offering new opportunities for creativity and efficiency.

Moreover, as sustainability becomes a growing concern, laser engraving technology is likely to focus on reducing energy consumption and waste. This could lead to the development of more eco-friendly machines and processes, aligning with global efforts to minimize environmental impact.

In conclusion, laser engraving machines are not just tools; they are gateways to innovation, offering endless possibilities for those willing to explore their potential.