A Comprehensive Guide to Forklifts and Their Role in Modern Industry

Understanding the Basics of Forklifts

The term forklift refers to a powered industrial truck used to lift and move materials over short distances. These machines are essential in warehouses, manufacturing plants, and distribution centers. From loading docks to inventory storage, forklifts provide the necessary support to handle goods efficiently and safely. Whether you’re managing a large warehouse or a small storage area, a forklift can significantly reduce manual labor and increase productivity.

Forklifts come in various types and sizes, each designed for specific applications. Common categories include electric forklifts, internal combustion forklifts, and rough terrain forklifts. The choice depends on factors such as load capacity, operating environment, and fuel preference. For instance:

- Electric models are ideal for indoor use and offer low emissions.

- Internal combustion forklifts are suited for heavy lifting and outdoor operations.

- Rough terrain forklifts are built for uneven surfaces and construction sites.

Understanding these basics helps determine the most suitable forklift for your operational needs.

Benefits of Using Industrial Forklifts

Industrial forklifts bring various advantages to businesses that deal with heavy materials or high-volume logistics. One of the key benefits is enhanced efficiency. By automating the lifting and transportation of goods, forklifts reduce the time and manpower needed for these tasks. This translates to faster workflows and potentially lower labor costs.

Safety is another critical benefit. Using a forklift minimizes the physical strain on workers and lowers the risk of injuries associated with manual handling. In addition, modern models are equipped with safety features such as backup alarms, load sensors, and stability control systems.

Forklifts are also highly versatile. They can be used in diverse environments, including:

- Warehouse operations

- Construction sites

- Shipping docks

- Retail distribution centers

Choosing the right industrial forklift can lead to significant operational improvements across these sectors.

Buying a Forklift: What to Consider

If you’re in the market for a forklift for sale, several factors should guide your decision. First, evaluate your specific needs, such as the average weight of loads, lift height requirements, and the nature of the terrain where the forklift will operate. Next, consider the fuel type—electric forklifts are eco-friendly and cost-effective for indoor use, while diesel or propane models offer greater power for outdoor tasks.

Budget is another major consideration. New forklifts offer the latest technology and warranty coverage but come at a higher price. On the other hand, used forklifts can provide excellent value if purchased from a reputable source. When exploring used machinery options, always check:

- Service history and maintenance records

- Operating hours

- Condition of tires and forks

- Compliance with safety standards

Doing thorough research and working with trusted vendors will help ensure a reliable investment.

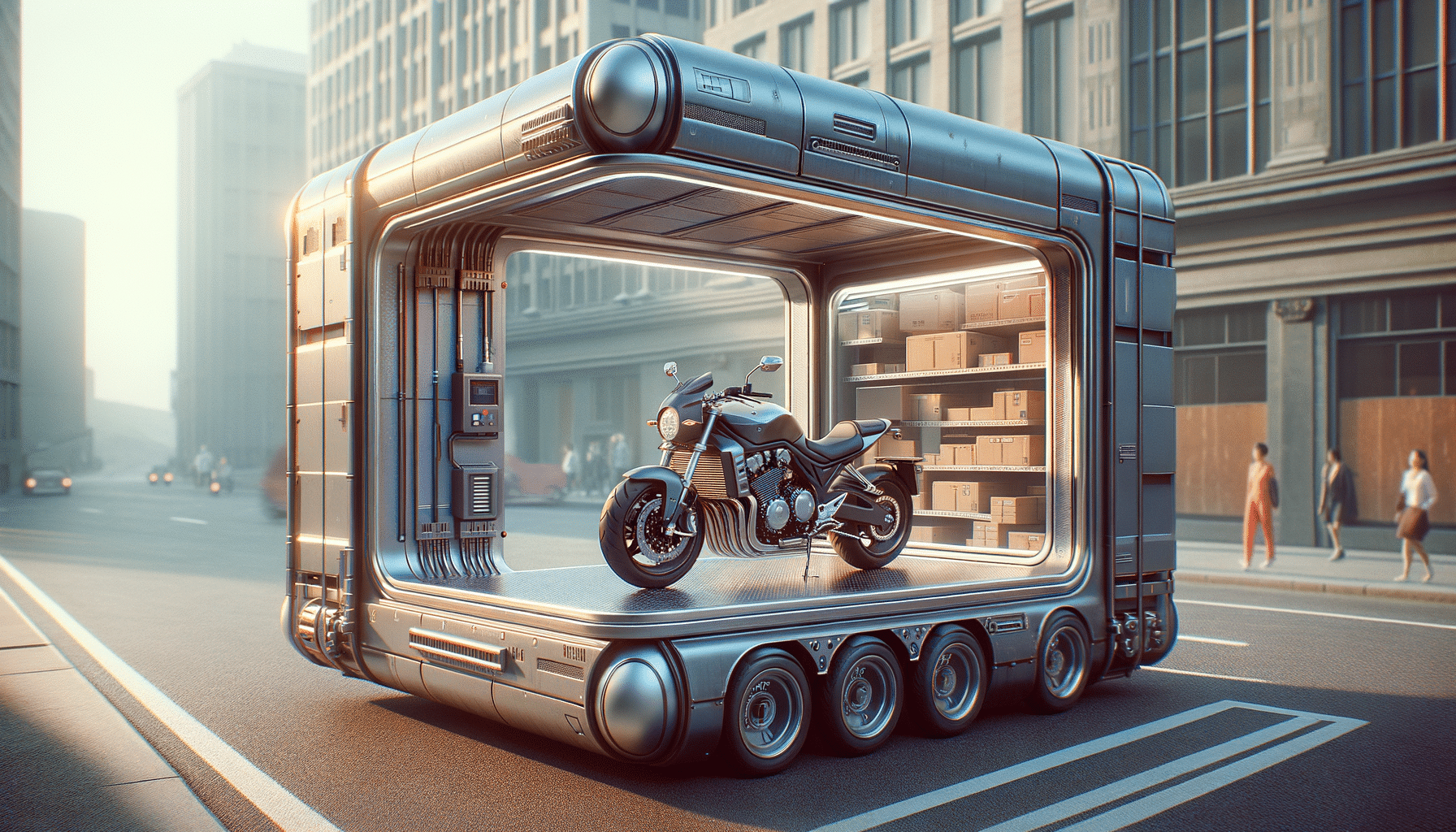

Advantages of Buying Used Forklifts

Used forklifts present a practical solution for businesses looking to manage expenses while maintaining operational efficiency. These machines often come at a fraction of the cost of new models, making them accessible to smaller businesses or those with limited capital. However, affordability doesn’t necessarily mean compromising on quality.

Many used forklifts have been well-maintained and can perform just as effectively as newer models. Reputable dealers often refurbish and inspect used machinery to ensure safety and functionality. Here are some reasons why used forklifts are worth considering:

- Lower upfront investment

- Reduced depreciation

- Immediate availability

- Proven performance history

When choosing from available used forklifts, it’s important to match the equipment specifications with your operational needs. A well-chosen used forklift can serve reliably for years, especially when integrated into a proper maintenance schedule.

Choosing the Right Warehouse Forklifts

Warehouse forklifts are specifically designed to navigate tight spaces and handle palletized goods efficiently. They are typically electric-powered, making them suitable for indoor environments with strict emission and noise regulations. Choosing the right warehouse forklift involves understanding the layout of your facility, the height of your storage racks, and the average weight of goods handled.

Key features to look for in warehouse forklifts include:

- Compact design for maneuverability

- High lift capacity for vertical storage

- Energy-efficient motors

- Advanced safety features like anti-tip systems

In addition to these features, ergonomic design can improve operator comfort and reduce fatigue during long shifts. Proper training and regular maintenance are essential to maximize the equipment’s lifespan and ensure safe operation. Whether you’re expanding your facility or replacing old units, investing in the right warehouse forklift can streamline your logistics and inventory processes.

Conclusion

Forklifts are a cornerstone of efficient material handling across various industries. From choosing a new or used forklift for sale to selecting the right type for your operation—whether it’s an industrial forklift or one tailored for warehouse use—making informed decisions is crucial. Evaluating your needs, understanding equipment specifications, and working with trustworthy vendors can help you build a fleet that supports your business goals. For companies aiming to optimize logistics and reduce manual strain, forklifts remain an essential and worthwhile investment.