Affordable DTF Printers: Perfect for Startups and Small Businesses

The Rise of DTF Printing Technology

Direct to Film (DTF) printing technology is rapidly gaining popularity due to its versatility and efficiency in creating custom designs on textiles. Unlike traditional screen printing, which requires multiple steps and considerable setup time, DTF printing offers a streamlined process that is both cost-effective and time-saving. This technology involves printing designs onto a special film, which is then transferred onto fabric using heat and pressure. The result is a vibrant, durable print that can withstand multiple washes.

One of the significant advantages of DTF printing is its ability to work on a wide range of fabrics, including cotton, polyester, and blends, without compromising the quality of the print. This flexibility makes it an attractive choice for businesses looking to expand their product offerings. Additionally, DTF printing allows for intricate designs with a high level of detail, making it suitable for both simple logos and complex artwork.

Moreover, the environmental impact of DTF printing is minimal compared to traditional methods. The process uses less water and ink, reducing waste and making it a more sustainable option. As businesses and consumers become more environmentally conscious, DTF printing’s eco-friendly nature is a significant selling point.

- Versatility: Works on various fabric types without quality loss.

- Detail: Capable of producing intricate designs.

- Sustainability: Lower environmental impact due to reduced water and ink usage.

Comparing DTF to Other Printing Methods

When evaluating printing options, it’s essential to compare DTF with other popular methods such as screen printing and Direct to Garment (DTG) printing. Each method has its strengths, but DTF stands out in specific areas that make it particularly appealing for small to medium-sized businesses.

Screen printing has been a staple in the industry for decades, known for its durability and vibrant colors. However, it requires a significant upfront investment in screens and setup, making it less ideal for small orders or custom designs. DTF, on the other hand, is perfect for short runs and one-off designs, offering a cost-effective solution without sacrificing quality.

Direct to Garment (DTG) printing is another popular method, especially for detailed and multicolored designs. While DTG offers excellent print quality, it is best suited for cotton fabrics and may not perform as well on other materials. DTF printing, with its adaptability to various fabrics, provides a broader range of options for businesses looking to diversify their offerings.

- Screen Printing: High setup cost, ideal for large runs.

- DTG Printing: Excellent for detailed designs, limited to cotton fabrics.

- DTF Printing: Cost-effective for short runs, versatile fabric compatibility.

The Economic Benefits of DTF Printers

For startups and small businesses, investing in a DTF printer can be a strategic move that offers numerous economic benefits. The initial investment in DTF technology is relatively low compared to other printing methods, making it accessible for businesses with limited capital. Moreover, the operational costs associated with DTF printing are manageable, as it requires fewer resources and less time to produce high-quality prints.

One of the key economic advantages of DTF printing is its scalability. Businesses can start with small orders and gradually increase production as demand grows. This scalability is crucial for startups that need to manage cash flow effectively while still meeting customer expectations. Additionally, the quick turnaround time of DTF printing allows businesses to respond swiftly to market trends and customer requests, providing a competitive edge.

Furthermore, DTF printers enable businesses to offer personalized products, which can command higher price points and increase profitability. Customization is a growing trend in the market, with consumers willing to pay more for unique, personalized items. By leveraging DTF technology, businesses can tap into this lucrative market segment and boost their revenue streams.

- Low Initial Investment: Affordable entry point for small businesses.

- Scalability: Easily adjustable production levels to match demand.

- Customization: Opportunity to offer personalized products at premium prices.

Creative Applications of DTF Printing

DTF printing technology opens up a world of creative possibilities for businesses and individuals alike. Its ability to produce high-quality, detailed prints on various fabrics makes it an ideal choice for a wide range of applications. From custom apparel to promotional products, DTF printing can be used to create unique, eye-catching designs that stand out in the market.

One exciting application of DTF printing is in the fashion industry, where it can be used to produce limited edition clothing lines with intricate designs. Designers can experiment with bold colors and complex patterns, knowing that the prints will maintain their vibrancy and detail. This capability allows brands to differentiate themselves in a competitive market and cater to fashion-forward consumers.

In addition to fashion, DTF printing is also popular in the production of promotional items such as tote bags, caps, and t-shirts. Businesses can use these products as marketing tools, showcasing their brand in a visually appealing way. The ability to produce small quantities at a lower cost makes DTF printing an excellent option for limited-time campaigns or special events.

- Fashion Industry: Ideal for limited edition, high-detail clothing lines.

- Promotional Products: Cost-effective for branded merchandise.

- Market Differentiation: Allows brands to stand out with unique designs.

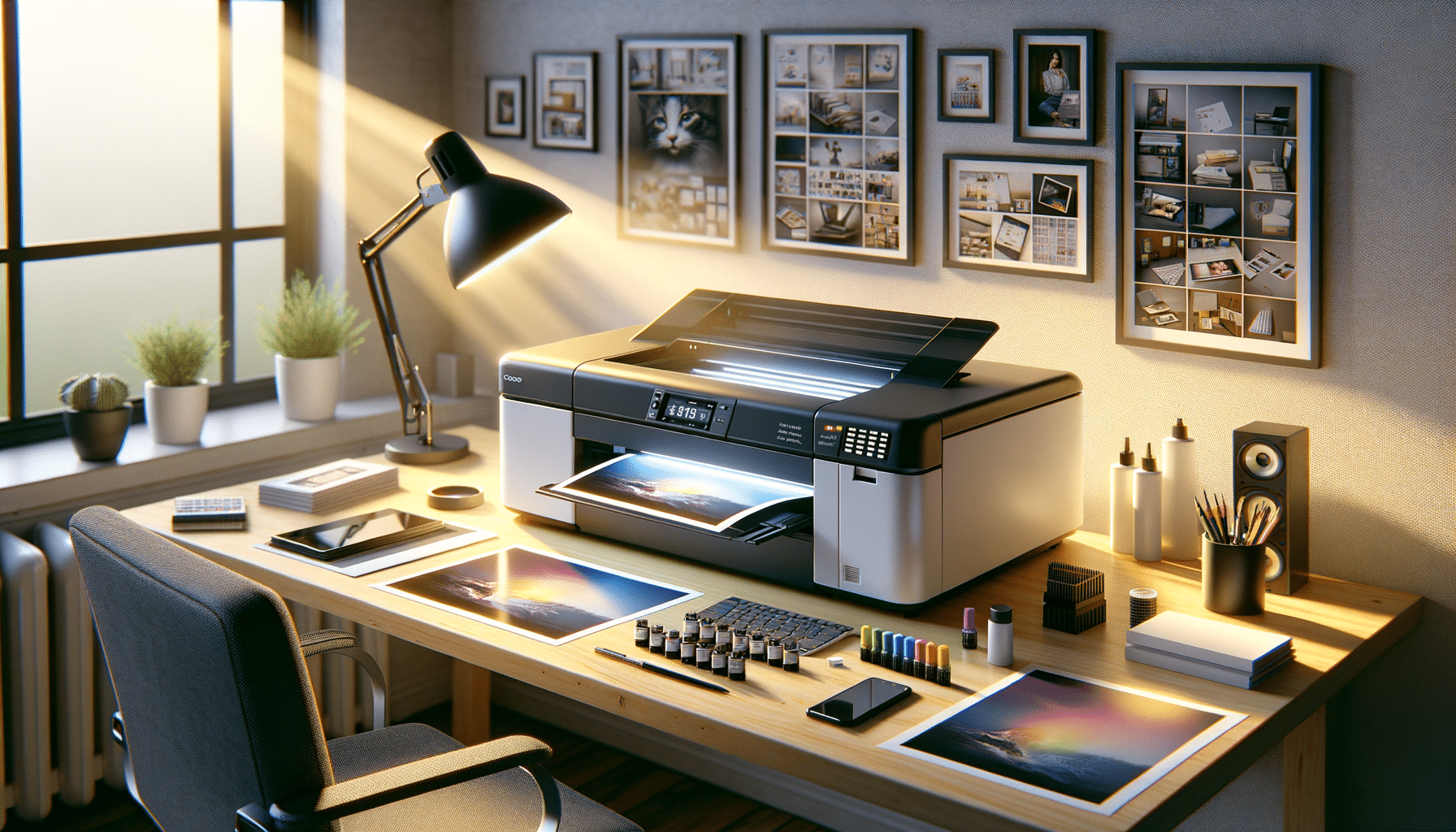

Choosing the Right DTF Printer for Your Needs

When selecting a DTF printer, it’s essential to consider several factors to ensure it aligns with your business needs and objectives. The first consideration is the printer’s capacity and speed, which should match your production requirements. For businesses looking to produce high volumes, investing in a printer with a faster printing speed and larger capacity will be beneficial.

Another critical factor is the quality of the prints. While most DTF printers offer excellent print quality, it’s important to evaluate the printer’s ability to produce vibrant colors and fine details consistently. This consistency is crucial for maintaining brand standards and ensuring customer satisfaction.

Additionally, consider the ease of use and maintenance of the printer. A user-friendly interface and straightforward maintenance procedures can save time and reduce operational costs. Some printers come with advanced features such as automated cleaning and maintenance alerts, which can further enhance efficiency.

- Capacity and Speed: Ensure it matches your production needs.

- Print Quality: Look for vibrant colors and fine detail consistency.

- Ease of Use: User-friendly interface and maintenance features.