An In-Depth Look at Outstanding Economical Hydraulic Press Machines

Hydraulic press machines are indispensable assets in numerous industries. Opting for a highly rated hydraulic press can provide notable advantages in terms of accuracy, convenience, and operational efficiency.

Understanding Hydraulic Press Machines

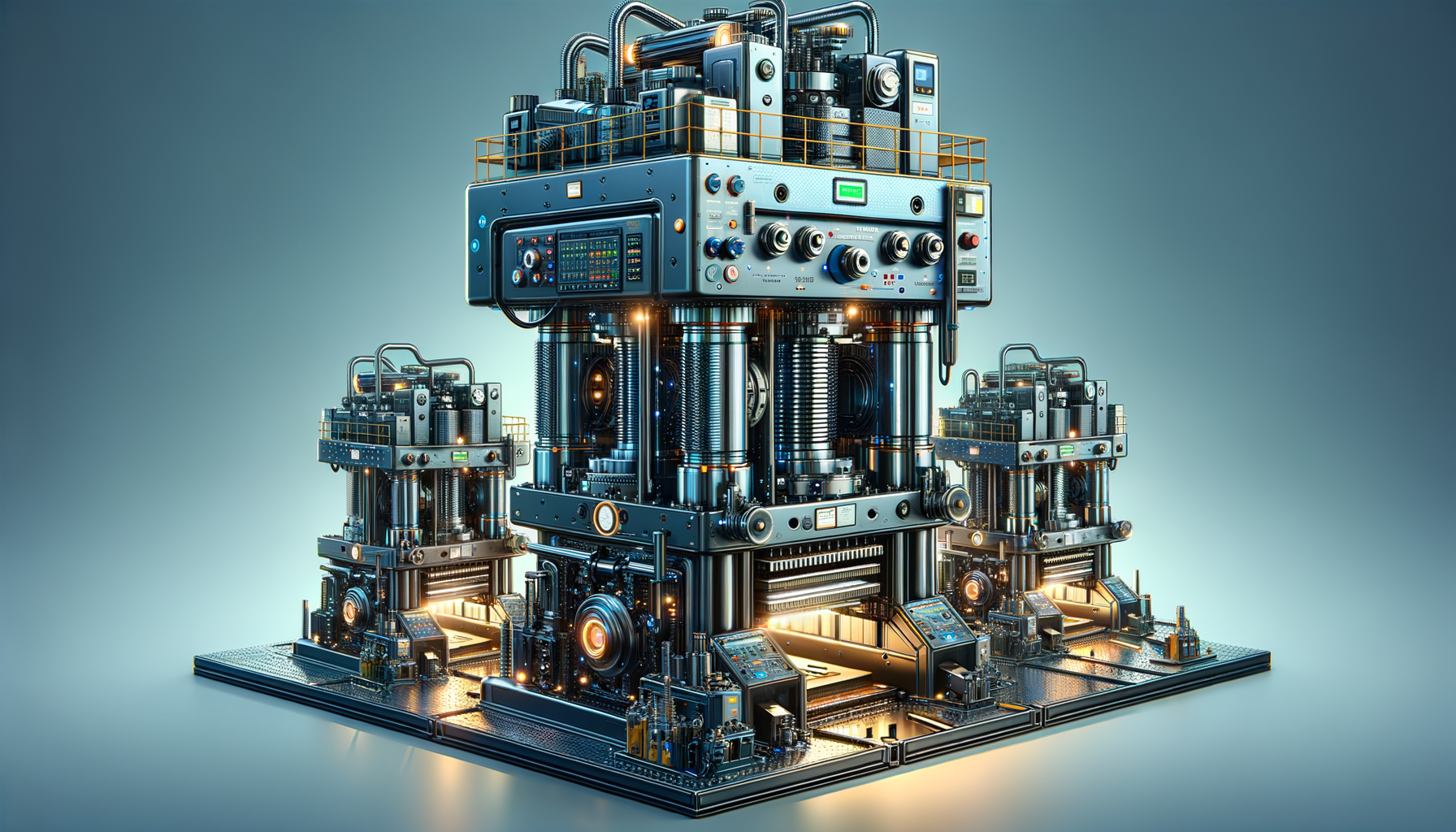

Hydraulic press machines have become essential tools in various industries, from automotive to manufacturing. These machines operate using a hydraulic cylinder to generate a compressive force. The fundamental principle behind hydraulic presses is Pascal’s law, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid. This allows the hydraulic press to exert substantial force with minimal input, making it a highly efficient tool for tasks such as metal forming, punching, and molding.

The versatility of hydraulic presses makes them suitable for a wide range of applications. They can be used in processes like forging, clinching, and deep drawing. Industries rely on these machines for their ability to deliver precise and consistent pressure, ensuring high-quality results. Moreover, hydraulic presses are known for their durability and long lifespan, which makes them a cost-effective investment for businesses looking to enhance their production capabilities.

Hydraulic press machines come in various configurations, including C-frame, H-frame, and four-post designs, each offering specific advantages depending on the application. The choice of a hydraulic press depends on factors such as the required force, the size of the workpiece, and the nature of the task. Understanding these aspects is crucial for selecting a machine that meets the specific needs of a business.

Features of Economical Hydraulic Press Machines

When considering hydraulic press machines, affordability does not mean compromising on quality. Many economical models offer features that rival more expensive counterparts. These machines often include adjustable pressure settings, allowing operators to fine-tune the force applied to match the requirements of different tasks. This flexibility is vital in ensuring precision and preventing damage to materials.

Another notable feature of affordable hydraulic presses is their user-friendly design. Many models come with intuitive controls and clear displays, making them accessible even to operators with limited experience. This ease of use can significantly reduce training time and increase productivity on the shop floor.

Additionally, economical hydraulic presses are often designed with energy efficiency in mind. They incorporate advanced hydraulic systems that minimize energy consumption while maximizing output. This not only reduces operational costs but also aligns with the growing emphasis on sustainable manufacturing practices.

These machines are typically built with robust materials to withstand heavy-duty use. Despite their affordability, they do not compromise on durability, ensuring that businesses can rely on them for consistent performance over time. This combination of features makes economical hydraulic presses a wise choice for companies looking to enhance their operations without breaking the bank.

Comparing Hydraulic Press Models

When selecting a hydraulic press machine, it’s essential to compare different models to find one that fits specific needs and budget constraints. Key factors to consider include the machine’s tonnage capacity, speed, and stroke length. Tonnage capacity determines the maximum force the press can exert, which is crucial for tasks that require significant pressure.

Speed is another critical factor, especially in high-volume production environments. Faster cycle times can lead to increased throughput, making a significant difference in overall productivity. However, it’s important to balance speed with precision to ensure quality output.

Stroke length, or the distance the press can travel, is also an important consideration. A longer stroke length allows for greater versatility in handling different sizes of workpieces. This flexibility can be particularly beneficial in industries that deal with a variety of products.

Comparing models also involves looking at additional features such as automation capabilities, safety mechanisms, and maintenance requirements. Some machines offer advanced automation options that can further enhance efficiency and reduce the need for manual intervention. Safety features, such as emergency stop buttons and protective guards, are crucial in preventing accidents and ensuring a safe working environment.

Ultimately, the choice of a hydraulic press should be guided by a thorough evaluation of these factors, ensuring that the selected model meets the specific demands of the intended application.

Applications and Benefits of Hydraulic Press Machines

Hydraulic press machines are indispensable in a variety of industrial applications due to their ability to apply significant force with precision. One of the primary uses of hydraulic presses is in metal forming processes, where they shape and mold metal parts with high accuracy. This capability is crucial in industries such as automotive manufacturing, where precision components are essential.

In addition to metal forming, hydraulic presses are widely used in the production of plastic and rubber products. Their ability to maintain consistent pressure ensures uniformity in the final products, which is vital for quality control. Furthermore, hydraulic presses are instrumental in tasks like powder compaction, where they compress powder into solid forms, commonly used in the pharmaceutical and ceramic industries.

The benefits of hydraulic press machines extend beyond their versatility. They offer advantages such as reduced labor costs and increased production efficiency. By automating tasks that would otherwise require manual labor, hydraulic presses can significantly lower operational expenses. Additionally, their ability to perform repetitive tasks with precision enhances overall productivity.

Another notable benefit is the safety and reliability of hydraulic presses. Equipped with advanced safety features, these machines minimize the risk of accidents, ensuring a safer working environment. Their robust construction and reliable performance also mean less downtime and maintenance, contributing to long-term cost savings.

Overall, the applications and benefits of hydraulic press machines make them an invaluable asset in modern manufacturing, providing businesses with the tools they need to stay competitive in a rapidly evolving market.

Choosing the Right Hydraulic Press for Your Needs

Selecting the right hydraulic press machine involves careful consideration of various factors to ensure it meets the specific needs of your business. The first step is to identify the primary applications and the type of materials you will be working with. This will help determine the necessary tonnage capacity and features required for optimal performance.

It’s also important to consider the available space in your facility. Hydraulic presses come in different sizes, and ensuring that the machine fits comfortably within your workspace is crucial. Additionally, consider the power supply requirements and whether your facility can accommodate them.

Another key factor is the level of automation desired. Some hydraulic presses offer advanced automation features that can enhance efficiency and reduce the need for manual intervention. While these features may come at a higher cost, they can lead to significant long-term savings by increasing productivity and reducing labor expenses.

Budget considerations are also important. While it’s tempting to opt for the most affordable option, it’s essential to balance cost with quality and reliability. Investing in a high-quality hydraulic press, even if it requires a higher initial investment, can result in better performance and lower maintenance costs over time.

Finally, consider the reputation and support offered by the manufacturer. A well-regarded manufacturer will provide reliable customer support and service, ensuring that any issues with the machine are promptly addressed. This can be invaluable in maintaining smooth operations and minimizing downtime.

By carefully evaluating these factors, businesses can select a hydraulic press that aligns with their specific needs and enhances their operational capabilities.