Lift with Confidence: High-Quality Car Jacks for Safe Repairs

Proper knowledge and usage of car jacks are essential for safe and efficient car repair operations.

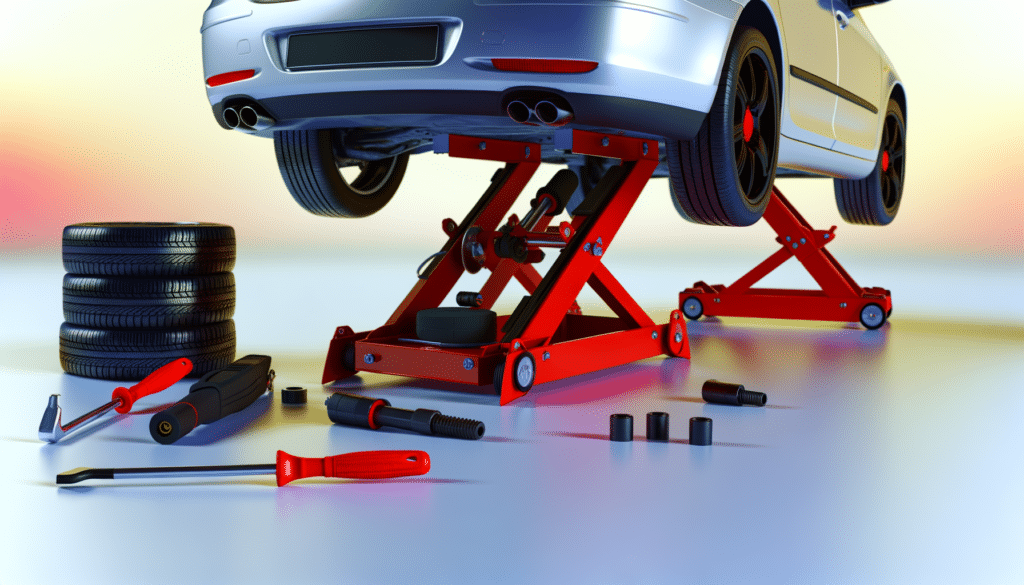

Types of Car Jacks

Understanding the different types of car jacks available is crucial. The most common types are scissor jacks, hydraulic jacks, and bottle jacks. Scissor jacks are usually supplied by car manufacturers for emergency tire changes. They are lightweight, compact, and relatively easy to use with a hand crank. However, their lifting capacity is somewhat limited. Hydraulic jacks, also known as floor jacks, are widely favored in workshops due to their ease of use and higher lifting capacity. These jacks utilize a hydraulic mechanism to lift vehicles smoothly and with less manual effort. Bottle jacks, another hydraulic type, resemble a bottle in shape and can lift heavier loads compared to scissor jacks. It’s important to choose the right type of jack for your specific needs, considering factors such as the weight of your vehicle and the nature of the repair work.

Using Car Jacks Safely

Safety is paramount when using car jacks. Always ensure that you are on a flat, stable surface before raising your vehicle. Uneven or soft surfaces can compromise the jack’s stability and pose serious risks. Use wheel chocks to prevent the vehicle from rolling while elevated. Ensure the jack is positioned correctly under the designated lifting points of the vehicle, which are usually reinforced areas indicated in the car’s manual. Never place any part of your body under the vehicle unless it is securely supported by jack stands. Jack stands provide added stability and safety, allowing you to work beneath the car with confidence. It is advisable to check the condition of your jack and stands regularly for any signs of wear or damage. Always follow the manufacturer’s instructions regarding weight limits and proper usage techniques to ensure a safe working environment.

Maintenance and Inspections

Regular maintenance and inspection of your car jack can extend its lifespan and ensure it operates safely. Hydraulic jacks should have their fluid levels checked periodically. Low fluid levels can affect the jack’s lifting capability and could lead to failure. Look for any fluid leaks, cracks, or corrosion on metal parts, which might indicate the need for repair or replacement. Lubricate moving parts as recommended by the manufacturer to ensure smooth operation. It’s also crucial to store your jack in a dry environment to prevent rust and corrosion. Regularly inspect the jack stands for any deformations or cracks and ensure that the locking mechanisms are functioning correctly. Keeping a maintenance log can help you keep track of inspections and any maintenance performed, ensuring your equipment remains in optimal condition.

Common Issues and Troubleshooting

Understanding common issues that can arise with car jacks and how to troubleshoot them is beneficial. One issue is the jack not lifting the vehicle. This could be due to low hydraulic fluid levels, which can be resolved by adding the appropriate fluid. Another problem might be air trapped in the hydraulic mechanism, which can be fixed by bleeding the jack as per the manufacturer’s instructions. If a scissor jack’s screw mechanism becomes hard to turn, applying a suitable lubricant can help. For all car jacks, if the lifting mechanism feels unstable or erratic, it’s crucial to stop using it immediately and inspect for any visible damages. In the event of severe mechanical issues, seeking professional repair services or replacing the jack altogether ensures that your safety is not compromised.

Legal and Practical Considerations

When working with car jacks, it is important to be aware of any local regulations or guidelines regarding car repairs to ensure compliance. Some jurisdictions may have specific rules about where and how car repairs can be conducted. For instance, there may be restrictions on performing repairs on public roads or requiring specific safety measures to be in place. Additionally, always keep yourself updated with any recalls or safety notices from the jack’s manufacturer. Adhering to these legal guidelines is not only crucial for your safety but also to avoid any potential fines or legal issues. Practically, it’s also wise to have a good understanding of your vehicle’s weight and lifting requirements, ensuring that your car jack is appropriately rated for the tasks at hand. Investing in high-quality and certified jacks and safety equipment can make a significant difference in terms of reliability and safety. By staying informed and cautious, you can ensure that your car repair activities are both safe and compliant.