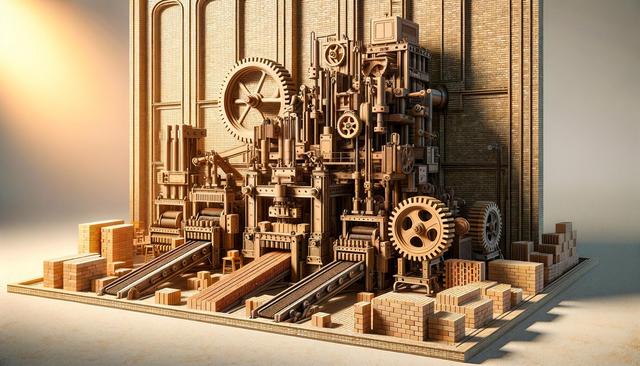

Exploring Brick Machines: Transforming Construction with Modern Technology

The Evolution of Brick Making Machines

Brick making machines have significantly advanced from traditional manual methods to highly automated systems. Historically, bricks were formed by hand and dried in the sun, a labor-intensive and time-consuming process. Today, modern machinery has made it possible to produce bricks more efficiently, consistently, and in vast quantities. These machines are designed to cater to different materials and production needs, offering solutions for both large-scale industrial use and smaller construction projects.

One of the most notable advancements in this field is the development of the concrete brick making machine. This type of equipment uses a mixture of cement, sand, and other aggregates to produce durable concrete bricks. These machines not only enhance production speed but also improve the quality of the final product. With adjustable molds and automation, manufacturers can meet diverse construction requirements with ease.

Types of Brick Machines and Their Functions

There are several types of brick machines available today, each tailored to specific materials and production goals. Understanding the differences can help businesses and builders choose the right equipment for their needs. Common types include:

- Concrete brick machine: Ideal for producing high-strength concrete bricks for structural use.

- Cement brick making machine: Often used for hollow or solid bricks made from cement and other materials.

- Compressed earth block machine: Utilizes natural soil and stabilizers to create eco-friendly building blocks.

- Compressed block machine: Designed for high-pressure molding of different types of blocks, including earth and cement blocks.

Each machine type has its own unique benefits, from environmental sustainability to cost-effectiveness, making them suitable for different geographic regions and project scales.

Benefits of Modern Brick Making Technology

Modern brick making machines offer a wide range of advantages over traditional methods. These benefits are not only limited to the efficiency of production but also extend to labor, cost, and environmental impact. Key advantages include:

- Consistent brick quality and dimensions

- Increased production capacity with reduced manpower

- Lower material wastage due to precision mixing and molding

- Eco-friendly options with compressed earth and minimal cement usage

- Customization possibilities with interchangeable molds

Brick making machine manufacturers continually innovate to integrate automation and smart controls, allowing operators to monitor and adjust production in real time. This level of control ensures that the bricks meet the necessary standards for strength and durability.

Choosing the Right Brick Making Equipment

When selecting a brick machine, several factors should be considered to ensure it aligns with the intended use and production goals. For example, a small contractor may benefit more from a compact and manually operated cement brick making machine, while large-scale operations may require a fully automated concrete brick machine. Key considerations include:

- Type of raw materials available

- Desired brick size and type

- Production volume requirements

- Budget and maintenance costs

- Availability of technical support from manufacturers

Working with reputable brick making machine manufacturers is crucial. They can provide guidance on the most suitable machine, offer after-sales support, and ensure the equipment complies with safety and quality standards.

Future Trends in Brick Machine Technology

The brick manufacturing industry is continuously evolving, with new technologies shaping the future of construction. One of the emerging trends is the integration of sustainability into machine design. Compressed earth block machines are gaining popularity due to their minimal environmental impact and utilization of local materials, reducing transportation emissions and costs.

Another trend is the use of digital technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) in brick making machines. These innovations allow for predictive maintenance, remote monitoring, and enhanced quality control. As these technologies become more accessible, they are likely to be adopted even by smaller manufacturers and contractors.

Additionally, the demand for modular construction components is influencing the design of brick machines, encouraging the development of equipment capable of producing a wider variety of shapes and sizes. This flexibility supports modern architectural needs and helps reduce on-site labor and construction time.