Exploring the World of Portable Sawmills

Introduction to Portable Sawmills

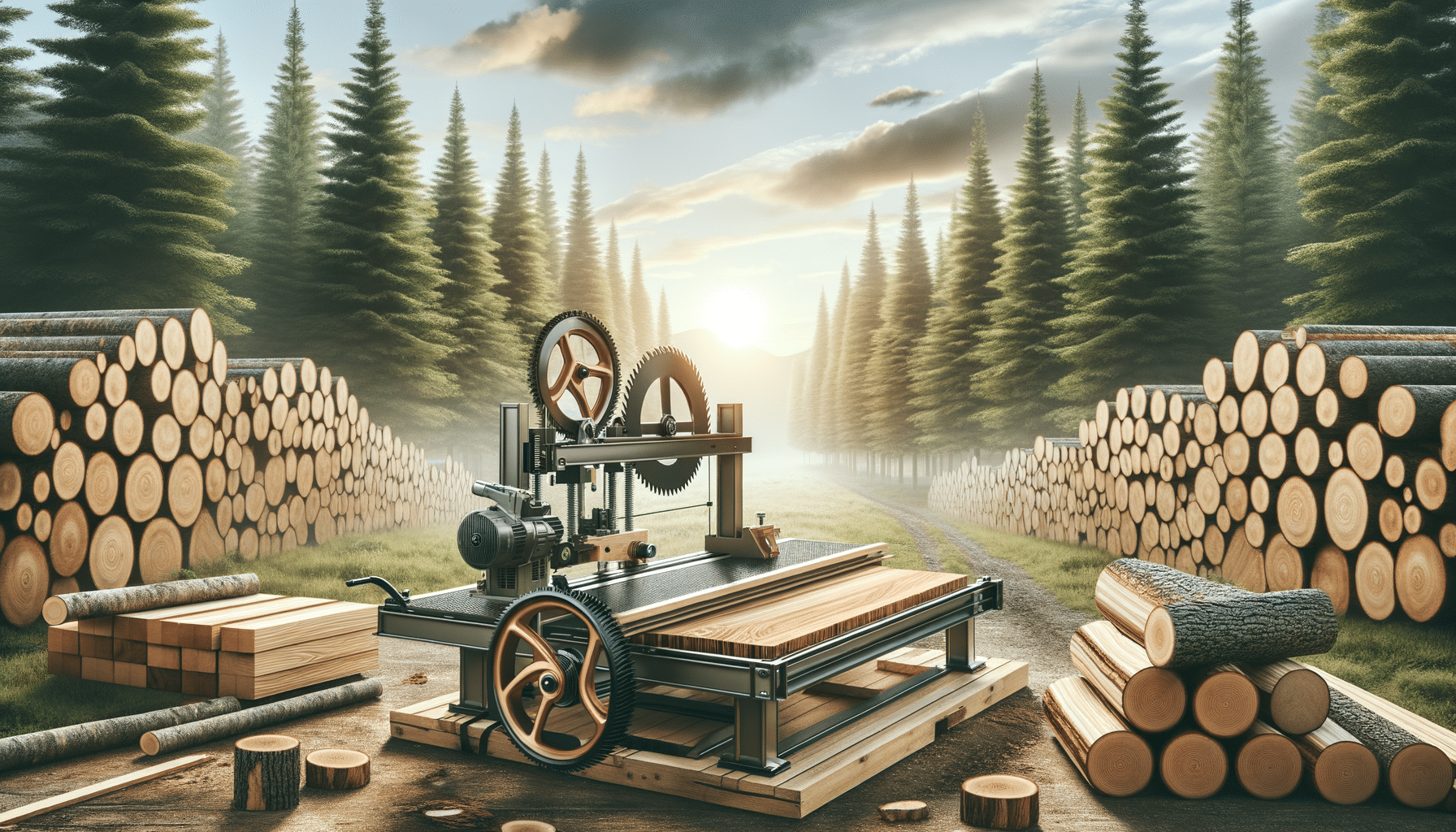

In the world of timber processing, portable sawmills have emerged as a game-changer, providing flexibility, efficiency, and accessibility. These compact machines allow individuals to cut logs into lumber on-site, eliminating the need for transporting heavy logs to a stationary mill. This innovation not only saves time and money but also opens up new opportunities for small-scale and independent operators. With the increasing demand for sustainable and locally sourced wood, portable sawmills are becoming an indispensable tool for many in the forestry and woodworking industries.

The Mechanics of Portable Sawmills

Understanding how portable sawmills operate is key to appreciating their value. These machines typically consist of a saw head, which houses the blade, mounted on a track that allows it to move along the length of the log. The saw head can be adjusted to different heights to produce various thicknesses of lumber. Portable sawmills are often powered by gas, diesel, or electric engines, providing the necessary force to cut through large logs efficiently.

The design of portable sawmills allows for easy transportation and setup in remote locations. Many models are equipped with wheels or trailers, enabling users to tow them behind vehicles. This mobility is particularly beneficial for those working in areas with limited infrastructure or access. Additionally, some advanced models come with features such as hydraulic log loaders and computer setworks, enhancing precision and reducing manual labor.

Benefits of Using Portable Sawmills

Portable sawmills offer a range of benefits that make them an attractive option for both hobbyists and professionals. Some of these advantages include:

- Cost-Effectiveness: By processing logs on-site, users can significantly reduce transportation costs and minimize waste.

- Flexibility: Portable sawmills can be used in various locations, allowing operators to access timber in remote or difficult-to-reach areas.

- Customization: Users can cut lumber to specific dimensions, catering to unique project requirements and maximizing resource utilization.

- Sustainability: By enabling local processing, portable sawmills reduce the carbon footprint associated with transporting raw materials.

These benefits make portable sawmills a valuable investment for those looking to optimize their wood processing operations.

Choosing the Right Portable Sawmill

When selecting a portable sawmill, several factors should be considered to ensure it meets your specific needs. Key considerations include:

- Log Capacity: Determine the maximum log diameter and length the sawmill can handle, ensuring it aligns with your typical workload.

- Power Source: Choose between gas, diesel, or electric models based on availability and cost of power in your area.

- Portability: Assess how easily the sawmill can be transported and set up, especially if you plan to move it frequently.

- Additional Features: Consider any additional features such as hydraulic log handling or computerized controls that could enhance productivity.

By evaluating these factors, you can select a portable sawmill that will effectively support your woodworking endeavors.

Conclusion: The Future of Portable Sawmills

As the demand for sustainable and locally sourced wood continues to grow, portable sawmills are poised to play an increasingly important role in the timber industry. Their ability to provide on-site processing, reduce costs, and offer customization makes them a valuable asset for both small-scale operators and larger enterprises. As technology advances, we can expect to see further innovations in portable sawmill design, enhancing their efficiency and capabilities.

For anyone involved in forestry or woodworking, investing in a portable sawmill could be a strategic move towards achieving greater independence and sustainability in their operations.