Harnessing Precision: The Role of Lathe Machines in Metal and Woodworking

The Evolution of Lathe Machines: A Historical Perspective

Lathe machines have a storied history that dates back to ancient times, with their earliest forms appearing in Egypt and Greece. Initially, these rudimentary devices were powered manually, but they laid the groundwork for the sophisticated machinery we see today. Over the centuries, lathe machines have evolved significantly, with the Industrial Revolution acting as a pivotal moment in their development. During this period, the introduction of steam power and later electricity transformed lathes into the more efficient and versatile machines used in modern engineering.

The evolution continued into the 20th century with the advent of computer numerical control (CNC) technology, which revolutionized precision in machining. CNC lathes allowed for automated control, enhancing accuracy and productivity. Today, lathe machines are indispensable in both wood and metalworking industries, embodying a blend of traditional craftsmanship and cutting-edge technology.

Understanding this historical progression highlights the importance of lathe machines in shaping industrial practices and underscores their enduring relevance in contemporary engineering.

Types of Lathe Machines: Diverse Applications

Lathe machines are categorized based on their specific functions and the materials they work with. Each type is designed to meet the demands of different applications, ensuring precision and efficiency. The most common types include:

- Engine Lathes: Known for their versatility, engine lathes are used for general-purpose machining. They can handle a variety of materials, making them a staple in many workshops.

- Turret Lathes: These are ideal for repetitive production tasks. With a turret that holds multiple tools, they allow for quick and efficient switching between operations.

- Toolroom Lathes: Designed for precision work, toolroom lathes are essential in manufacturing high-quality tools and dies.

- Wood Lathes: Specifically for woodworking, these lathes are used to shape and finish wood pieces, from furniture to decorative items.

- CNC Lathes: Offering unparalleled precision, CNC lathes are controlled by computer programs, making them suitable for complex and high-volume production tasks.

Each type of lathe machine brings unique capabilities, contributing to their widespread use across various industries, from automotive to aerospace and beyond.

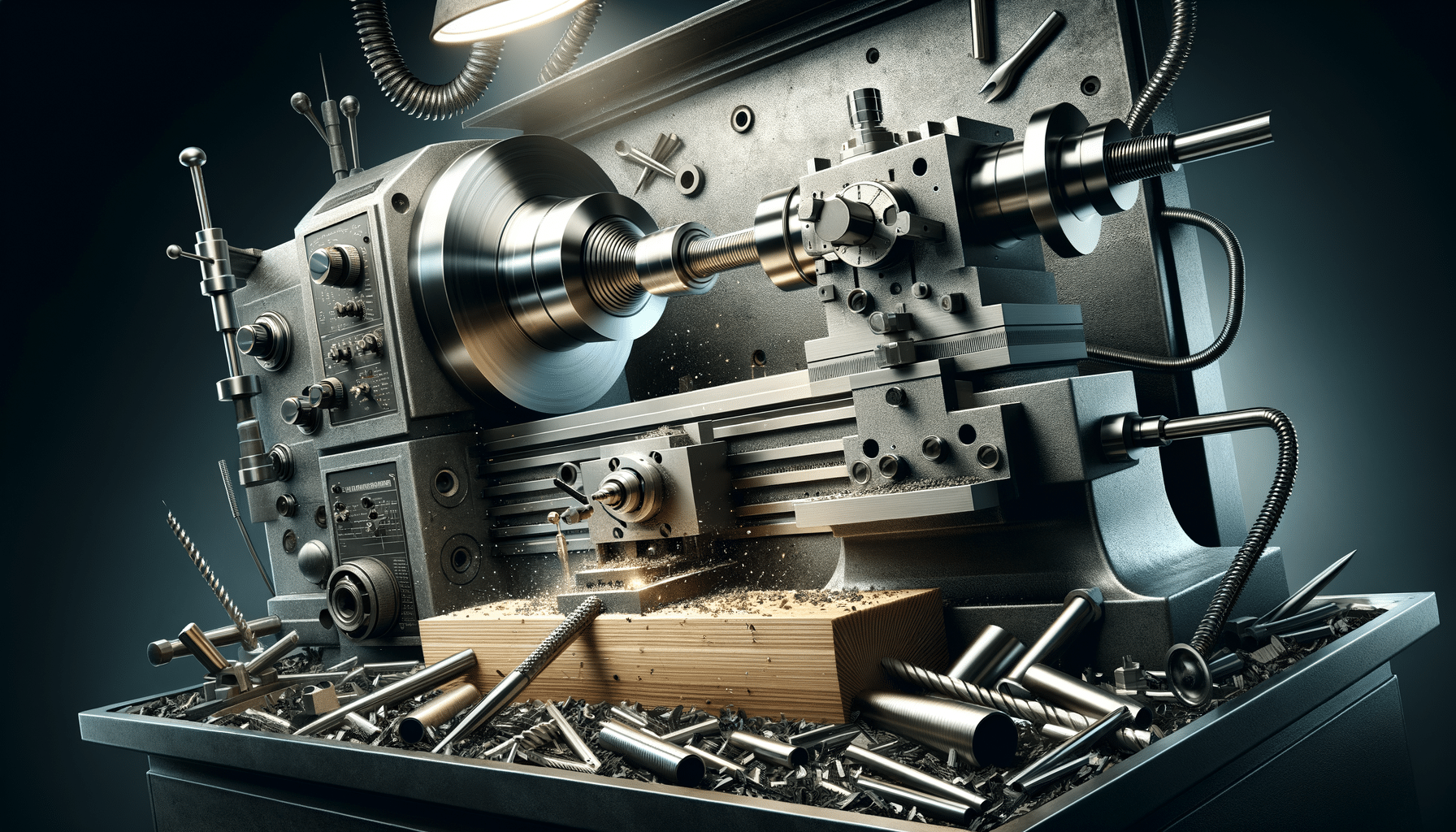

Precision in Engineering: The Key Role of Lathe Machines

Precision is a critical factor in engineering, and lathe machines play a crucial role in achieving it. Whether in metalworking or woodworking, these machines are designed to perform tasks with exactitude, ensuring that the final products meet stringent specifications. This precision is vital in industries where even the smallest deviation can lead to significant issues.

In metalworking, for instance, lathe machines are used to create components that fit perfectly together, such as gears and shafts. The ability to produce parts with exact dimensions ensures the smooth operation of machinery and extends the lifespan of equipment. Similarly, in woodworking, lathes are used to craft intricately detailed pieces, where precision enhances the aesthetic and functional qualities of the product.

Advanced features such as CNC technology further enhance the precision capabilities of lathe machines, allowing for complex designs and high repeatability. This precision not only improves the quality of the products but also optimizes production efficiency, reducing waste and increasing profitability.

Comparing Wood and Metal Lathe Machines

While both wood and metal lathe machines share the fundamental principle of rotating a workpiece against a cutting tool, they are designed differently to cater to the specific requirements of their respective materials. Understanding these differences is crucial for selecting the right machine for a given task.

Wood Lathes: These machines are generally simpler in design, focusing on shaping and finishing wood. They often feature adjustable speeds to accommodate different wood types and the desired finish. Wood lathes are typically lighter and less robust than their metal counterparts, reflecting the softer nature of wood.

Metal Lathes: In contrast, metal lathes are built to withstand the rigors of cutting through harder materials. They are more complex, with features such as coolant systems to prevent overheating and more powerful motors to handle the resistance of metal. Metal lathes also offer greater precision and control, essential for creating intricate metal components.

Choosing between a wood or metal lathe depends largely on the material being worked on and the specific requirements of the project. Each type of lathe offers distinct advantages, making them indispensable tools in their respective fields.

Future Trends: The Evolution of Lathe Machines

The future of lathe machines looks promising, with ongoing technological advancements set to enhance their capabilities further. One of the significant trends is the integration of smart technology, which is expected to bring about a new era of automation and efficiency. Smart lathes, equipped with sensors and IoT connectivity, will offer real-time monitoring and diagnostics, reducing downtime and improving maintenance.

Another trend is the continued advancement of CNC technology, which will enable even more complex and precise machining tasks. As industries demand higher accuracy and faster production times, CNC lathes will likely become even more prevalent, driving innovation in manufacturing processes.

Moreover, the push towards sustainability is influencing the development of lathe machines. Manufacturers are exploring eco-friendly materials and energy-efficient designs to reduce the environmental impact of machining operations. These trends indicate a future where lathe machines will not only be more efficient and precise but also more environmentally conscious.

In conclusion, lathe machines will continue to be a cornerstone of engineering, adapting to meet the evolving needs of industries worldwide.