Navigating the Market of Affordable CNC Machines: A Comprehensive Guide to Making the Right Choice

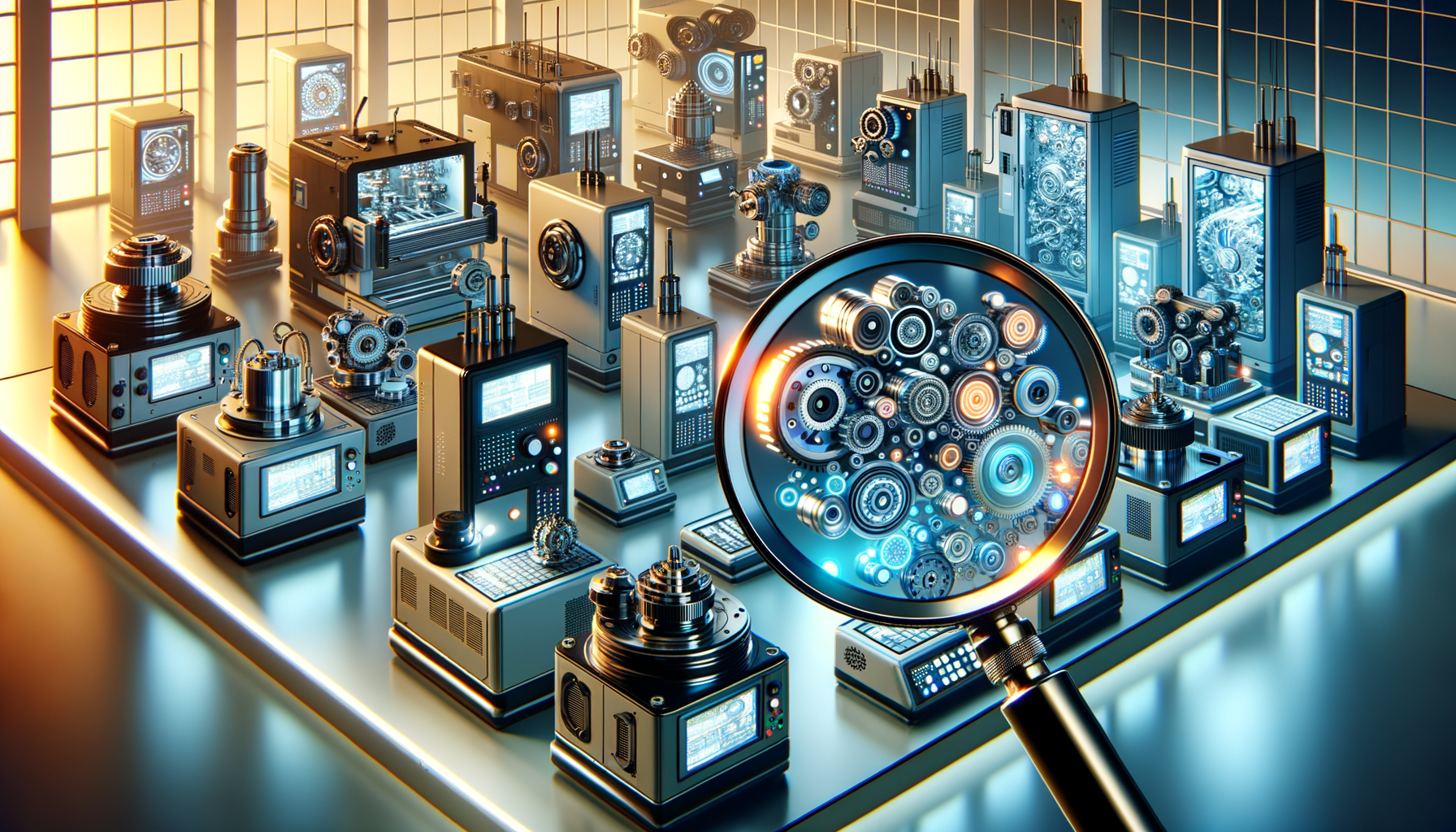

Understanding the Basics: What is a CNC Machine?

CNC, or Computer Numerical Control, machines are automated tools that follow programmed instructions to perform a range of tasks, from cutting and drilling to milling and engraving. These machines have revolutionized manufacturing by increasing precision, reducing labor costs, and enabling complex designs. In recent years, the market for CNC machines has expanded beyond large industrial settings to include more affordable options for small businesses and hobbyists.

The fundamental components of a CNC machine include a computer, a controller, and the mechanical components such as motors and spindles. The computer runs software that converts design files into a series of commands, which the controller then interprets to move the machine’s parts. This automation allows for high levels of accuracy and repeatability, making CNC machines a valuable asset in various industries.

Understanding the basics of CNC technology is crucial for anyone looking to invest in a machine. It helps in making informed decisions about the type of machine that would best suit specific needs, whether for creating intricate designs in a home workshop or streamlining production in a small business setting.

Exploring Cost-Effective CNC Machine Options

The availability of cost-effective CNC machines has opened up new opportunities for small businesses and hobbyists. These machines come in various forms, each designed to cater to different needs and budgets. From desktop CNC routers suitable for woodworking and engraving to more robust milling machines used in metalworking, the options are diverse.

When exploring affordable CNC machines, it’s essential to consider factors such as build quality, ease of use, and the range of materials the machine can handle. For instance, desktop CNC routers are often favored by hobbyists for their compact size and versatility, allowing them to work with wood, plastic, and soft metals. On the other hand, small-scale milling machines might be more appropriate for those needing to work with harder materials like steel or aluminum.

Another important consideration is the software compatibility and support offered by the manufacturer. Machines that come with user-friendly software and strong customer support can significantly enhance the user experience, especially for beginners. By carefully evaluating these factors, buyers can find a CNC machine that balances cost with functionality and reliability.

Key Factors to Consider When Choosing a CNC Machine

Selecting the right CNC machine involves assessing several key factors to ensure it meets your specific needs. One of the primary considerations is the intended application. Different machines are designed for different tasks, so understanding what you need the machine to do will guide your choice.

Another critical factor is the machine’s size and the available workspace. Larger machines might offer more capabilities but require more space and power. For those with limited space, compact models might be more suitable. Additionally, consider the machine’s speed and precision, especially if you plan to use it for detailed work or need to produce large quantities.

Budget is also a significant consideration. While it’s tempting to opt for the cheapest option, investing in a slightly more expensive machine with better features and durability can be more cost-effective in the long run. Evaluate the total cost of ownership, including maintenance, software updates, and potential upgrades, to make an informed decision.

Maintenance and Longevity: Ensuring Your CNC Machine Lasts

Proper maintenance is crucial to ensuring the longevity and performance of a CNC machine. Regular upkeep not only extends the machine’s lifespan but also maintains its accuracy and efficiency. Key maintenance tasks include keeping the machine clean, lubricating moving parts, and regularly checking for wear and tear.

Developing a maintenance schedule can help prevent costly breakdowns and downtime. This schedule should include daily, weekly, and monthly checks, such as cleaning the work area, inspecting electrical connections, and calibrating the machine. Additionally, keeping a log of maintenance activities can be beneficial for tracking performance and identifying potential issues early.

Investing in quality components and using the machine within its specified parameters can also enhance its longevity. Avoid overloading the machine or using it for materials it wasn’t designed to handle, as this can lead to premature wear. With proper care, a CNC machine can provide reliable service for many years, making it a worthwhile investment.

Future Trends: The Evolving Landscape of CNC Technology

The world of CNC technology is continually evolving, with new trends and innovations shaping the future of manufacturing. One significant trend is the integration of smart technology, which allows for more efficient and automated processes. Machines equipped with sensors and IoT capabilities can monitor their own performance and alert users to potential issues before they become critical.

Another emerging trend is the use of advanced materials and multi-axis machining, which expands the capabilities of CNC machines. These advancements enable the creation of more complex and intricate designs, pushing the boundaries of what is possible in manufacturing.

As technology continues to advance, the affordability and accessibility of CNC machines are likely to improve further. This evolution will empower more small businesses and individual creators, enabling them to compete in a market that was once dominated by large industrial players. By staying informed about these trends, users can make strategic decisions that align with future developments in the industry.