Navigating the Mechanics of Hydraulic Jacks

Introduction to Hydraulic Jacks

Hydraulic jacks have become an indispensable tool in various industries, known for their ability to lift heavy loads with minimal effort. These devices operate on the principle of hydraulics, where fluid pressure is used to generate force. This mechanism allows hydraulic jacks to lift loads that would otherwise be impossible with manual tools. The relevance of hydraulic jacks extends from automotive repairs to construction and even in some home applications. Understanding how these jacks function and their diverse applications can provide valuable insights into their importance in modern engineering and mechanics.

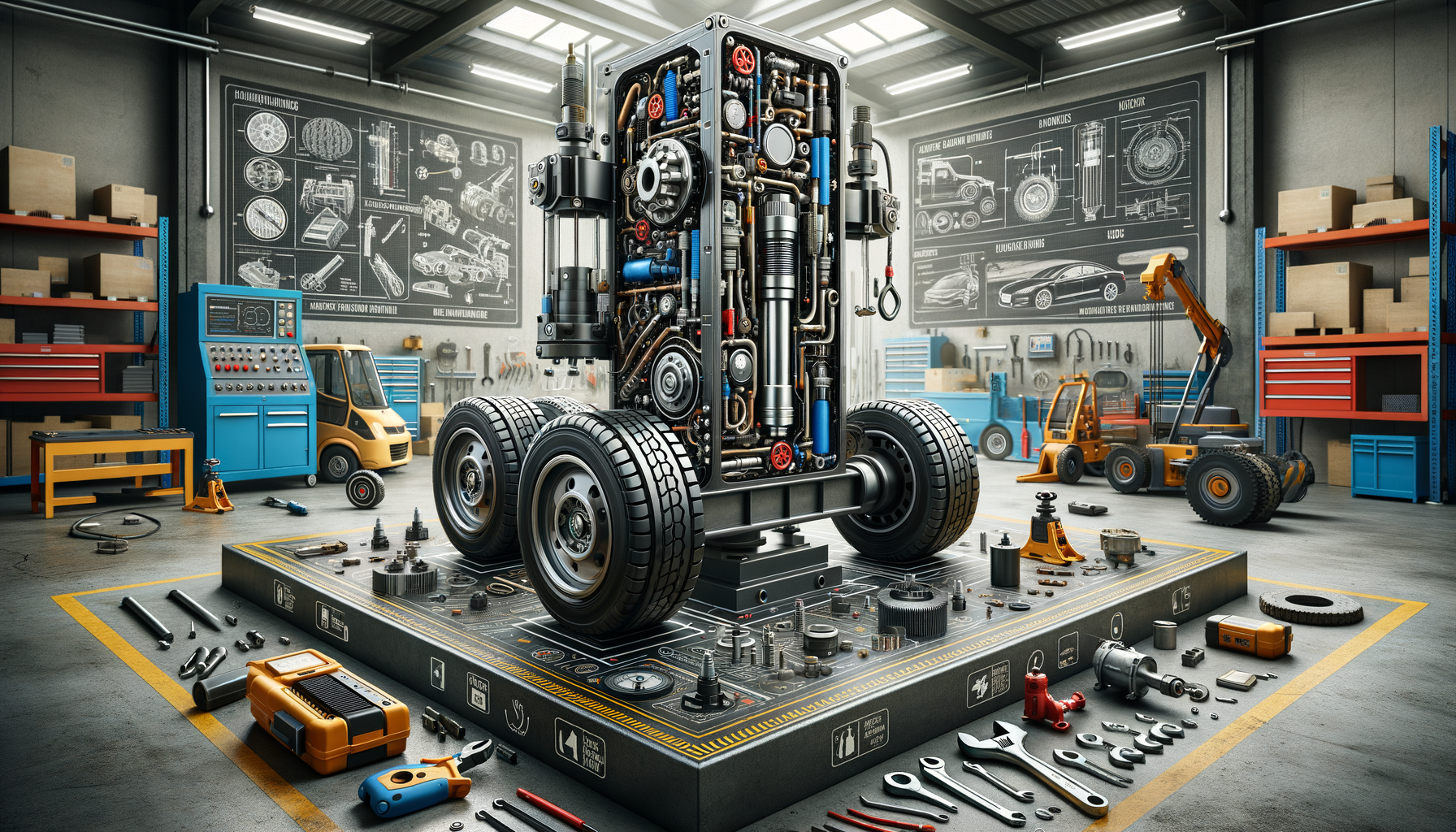

How Hydraulic Jacks Work

The basic operation of a hydraulic jack involves the use of a pump plunger to move oil through two cylinders. When the plunger is drawn back, oil is drawn out of the reservoir and into the pump chamber. As the plunger is pushed forward, the oil is moved into the cylinder, causing the piston to rise and lift the load. This process is repeated to achieve the desired height. The key components of a hydraulic jack include the reservoir, pump, check valves, and the main cylinder. The efficient transfer of force through hydraulic fluid allows these jacks to lift heavy weights with precision and ease.

Some advantages of hydraulic jacks include:

- High lifting capacity

- Precision in lifting

- Ease of use

- Durability and reliability

These attributes make hydraulic jacks essential in situations where heavy lifting is required, providing a reliable solution that maximizes efficiency and safety.

Applications of Hydraulic Jacks

Hydraulic jacks are used in a variety of applications across different industries. In the automotive industry, they are commonly employed for lifting vehicles to perform repairs and maintenance. Their ability to lift several tons makes them ideal for this purpose. In construction, hydraulic jacks are used to support and lift structures, ensuring safety during building and renovation projects. Additionally, they find applications in the railway industry for track maintenance and in the aerospace sector for aircraft maintenance.

Beyond industrial use, hydraulic jacks are also found in some home improvement projects, such as leveling floors or moving heavy furniture. Their versatility and power make them a practical choice for both professional and personal use.

Types of Hydraulic Jacks

There are several types of hydraulic jacks, each designed for specific purposes. The most common types include bottle jacks, floor jacks, and scissor jacks. Bottle jacks are known for their compact design and high lifting capacity, making them suitable for heavy-duty lifting tasks. Floor jacks, on the other hand, are designed for stability and ease of movement, often used in automotive workshops. Scissor jacks, while not purely hydraulic, incorporate hydraulic elements to enhance their lifting capability, commonly used in vehicle trunk kits for emergency tire changes.

Choosing the right type of hydraulic jack depends on the specific requirements of the task at hand. Factors such as lifting capacity, height, and portability should be considered to ensure optimal performance and safety.

Maintaining Hydraulic Jacks

Proper maintenance of hydraulic jacks is crucial to ensure their longevity and performance. Regular inspection for leaks, cracks, and other signs of wear is essential. It is also important to keep the hydraulic fluid clean and at the recommended level, as contaminated or low fluid can affect the jack’s efficiency. Lubricating moving parts and checking the seals for wear can prevent malfunctions and extend the life of the jack.

When not in use, storing hydraulic jacks in a dry, clean environment can protect them from rust and other environmental damage. By following these maintenance tips, users can ensure that their hydraulic jacks remain in good working condition, ready to perform when needed.

Conclusion: Embracing the Power of Hydraulic Jacks

Hydraulic jacks are a testament to the power of engineering, providing a simple yet effective solution for lifting heavy loads. Their applications across various industries highlight their importance and versatility. Whether in automotive repair, construction, or home improvement, hydraulic jacks offer a reliable and efficient means of achieving tasks that require significant lifting power. By understanding their operation, applications, and maintenance, users can fully embrace the capabilities of hydraulic jacks, ensuring they are used safely and effectively in all relevant scenarios.